STid is also working on another configuration tracking project for aircraft engine parts for the SAFRAN Group (Turbo Méca)

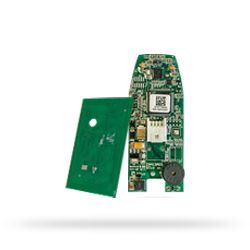

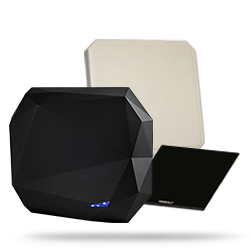

The concept is the same as for the Airbus Helicopters solution except that the data stored in each IronTag® (identifying each aircraft engine part) is read in real time by a built-in STid RFID reader

The on-board system then collects the data and associates it with engine sensor data (temperatures, vibrations, etc.)

All this precious data can then be transmitted via cable or WiFi

Benefits:

- Time-saver. The operator can read the data instantly

- Optimized engine configuration readings. For example, it will be possible to directly associate a component with a temperature that is too high with its last overhaul or maintenance or use history