AIRBUS HELICOPTERS selected STid for its "Helicopters of the Future" project

Client problem:

Quickly and accurately identify parts for new helicopters and be able to store all maintenance and supervision data on the parts

The goal is to optimize maintenance processes and the management of helicopter part service life cycles in order to better track aircraft quality

The challenge: Provide a comprehensive tracking solution that includes a range of RFID tags designed for difficult-to-reach metal environments and able to withstand harsh environments

Our solution:

A complete configuration and maintenance tracking tool that complies with ATA Spec. 2000 and RTCA DO-160 standards, integrating:

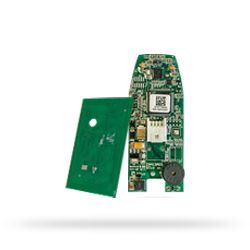

- IronTag® range specially developed for the aircraft manufacturer and integrated into each helicopter part

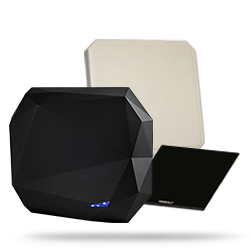

- UHF mobile terminal with customized software

With these tools, technicians will be able to automatically and accurately identify each aircraft part

In the past, these operations took up to a full day and can now be completed in just a few minutes

Benefits:

- Maintenance history embedded into each tag

- Reliable maintenance tracking

- Optimized engine configuration readings

- Time-saver

- Fewer FODs