With our partners CIPAM, Eurotherm and OMIA, we have developed a smart painting line system to monitor temperature and track parts for ASCO, a world leader in the design and manufacture of aeronautical equipment.

The four partners provide a comprehensive solution in terms of safety and reliability for ASCO’s demanding and explosive industrial environment (ATEX Zone 2 environment). They meet multiple needs:

- Tracking temperatures between the different zones in the painting line system (booth, desolvation zone, ovens),

- Controlling oven temperatures,

- Tracking and locating parts on the painting line in real time.

The goal? Provide optimized tracking of parts on the painting line for more efficient operations at ASCO.

? Explanation by Sébastien Wetz :

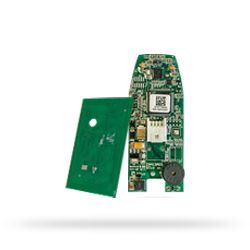

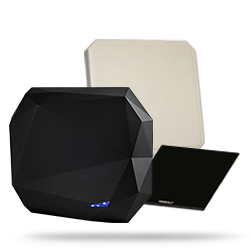

“We provided a solution for industrial parts identification and #tracking with our SPECTRE INDUSTRY and ATX readers, tailored to the most extreme environments.”

A project highlighted in GALVANO ORGANO eand presented by Vincent Routaboul from CIPAM.